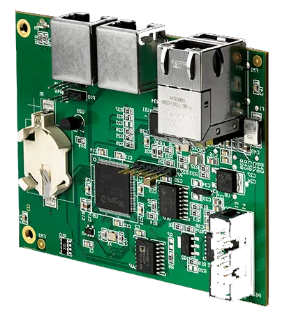

We handle your most advanced flex PCB requirements

Flex and rigid-flex boards require precise fabrication processes and engineering expertise in order to deliver foolproof products. Sierra Electrotek offers advanced capabilities for all your industry needs.

-

Flex-HDI (high-density interconnect)

-

Polyimide, Coverlay and high Tg materials

-

High-performance epoxy laminates and prepregs

-

Microsection report

-

Certificate of compliance

-

IPC Class 3/ES

The

PLUS

Our DFM engineers will make sure that your flex requirements are manufacturable and will contact you to discuss any potential issue that could cause delays.

Give us a call or send us an email to get started

on your project.